Anyone who has ever used public transportation in Rochester is painfully aware of two things: at some point you will have to wait for your bus, and when you do, you will probably be standing.

For senior citizens, people with disabilities, and parents with young children, being made to stand for any length of time can be less than ideal. Even for those passengers who are physically capable of standing, having no place to sit while waiting on the side of a busy roadway can cause anxiety and discomfort.

Why is our bus system the only transportation mode that requires its passengers to stand while waiting for the service? The single biggest issue is the sheer scale of the system. There are thousands of bus stops in the RTS network, and the resources of the transit authority are already spread thin.

If this issue could be remedied, not only would we make the lives of current riders a little easier, but we might also encourage more people to use public transportation. This is why Reconnect Rochester has decided to make bus stop seating a priority for our community.

A Solution

In 2014, Reconnect Rochester set out to find a solution. What we came up with was a design for a bus stop seat that is a simple 2’x2’x2’ cube. Our bus stop seating cube comes in 4 primary colors (red, green, yellow, and blue) that add beautification and brightness to the street landscape. The compact size allows the seat to fit easily within areas where space is at a premium – such as tree lawns or that little bit of space between the street curb and sidewalk.

In 2017, after 3 years piloting seasonal bus stop cubes made from high-pressured wood, Reconnect Rochester set out to find a permanent, year-round amenity for bus riders. In our research, we came upon a local manufacturer of fiberglass — a nearly indestructible, weather resistant material that was perfect for the job!

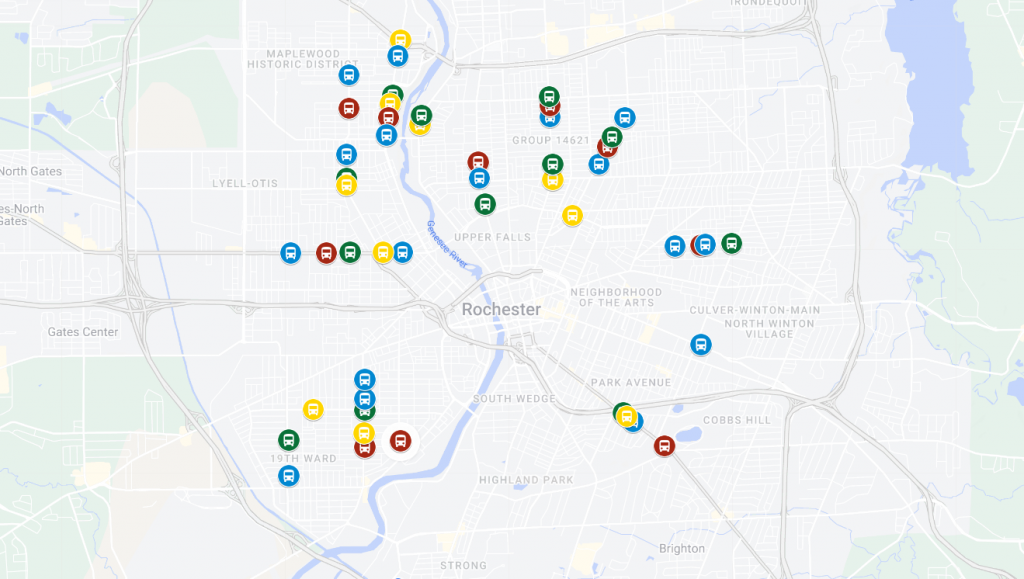

In September 2020, Reconnect Rochester installed the first 15 fiberglass cubes (read more in this blog post). In 2021, we installed an additional 16 cubes, and in 2022 another 23 cubes — that’s a total of 54 cubes on the ground! Stay tuned to our blog and social media for updates on our current efforts.

Cubes for Your Community

Reconnect Rochester will continue to work with RTS, local municipalities and community organizations throughout Monroe County to add bus stop cubes at stops that are well utilized but lack seating.

Would you like to see bus stop cubes at stops in YOUR neighborhood or community? Contact us and we’ll do our best to work with you to secure funding and make it happen.

Are you from outside the Monroe County area and interested in purchasing bus stop cubes for your town or city? Contact us and we’ll put you in touch with the manufacturer. Reconnect Rochester receives a sales commission that helps fuel our effort to put more bus stop cubes on the ground locally.

The Bus Cube Birth Story

The bus cube was born in 2014, when Reconnect Rochester set out to come up with a temporary solution to the dearth of seating at local bus stops. Here’s how we did it…

We spent countless hours brainstorming. We scoured the internet. And we even met with a local furniture designer, Staach (we really admire the way those guys balance form, function, and sustainability). But we needed something that would be relatively inexpensive and easy for regular people like us to build and duplicate. It would also need to be compact, sturdy, and weather resistant.

We could have simply taken a page from the guerilla bus stop seating playbook and chained a plastic patio chair to a bus stop sign, but to be honest, we’re not fans of plastic furniture. And we really didn’t think the neighbors would appreciate this look very much.

Then one day, almost like it happens in the movies, the solution hit us like a lightning bolt…good old-fashioned children’s blocks! It’s amazing how sometimes the best ideas are inspired by the simplest things. Children’s blocks. Durable, easy to use, easy to construct – and what could possibly be more fun? Quite fitting for Rochester, the home of the National Toy Hall of Fame!

We put pencil to paper and designed a simple 2’x2’x2’ cube. The compact size allows the seat to fit easily within areas where space is at a premium – such as tree lawns or that little bit of space between the street curb and sidewalk. Our prototype was constructed using pressure-treated lumber and decking materials for a total cost of about $100 per cube.

We tested the prototypes at two locations within the city of Rochester: The PriceRite at Dewey & Driving Park and N. Union St. at the Public Market. The results were very positive. Interviews with transit riders and passersby can be viewed in this video.

The idea quickly won community support as well as accolades from RTS which encouraged the effort. Over the next three years (2014 – 2017), in partnership with the City of Rochester, Flower City Habitat for Humanity and many neighborhood and community organizations, we built and placed a fleet of over 30 bus stop cubes at bus stops all around the city.

The seasonal cubes go out on the street in May and are brought back in and stored in October. As the fleet grew, the job performed by Reconnect Rochester volunteers of placing, removing and storing the cubes each season, became harder to manage. That’s when we decided it was time for a permanent, year-round solution.

It took about three years (2017 – 2020) of stops-and-starts to research, design and manufacture the fiberglass model that you see today. But we’ll save THAT story for another day.